High-precision microfluidic valves for automated fluid control

Our microfluidic rotary valves are engineered for ultra-low internal volume, no dead volume, reliable sample multiplexing, and seamless integration into automated lab and industrial fluidic systems. Whether you’re working in diagnostics, life sciences, or advanced manufacturing, AMF helps you achieve more precise, efficient, and scalable fluid control.

They trust us

Trusted by leaders in diagnostics, biotech, life science and lab automation.

What are microfluidic valves and how do they work?

There are several types of microfluidic valves used depending on system complexity and control needs:

- Passive valves – Operate without power, using fluid pressure or mechanical design to regulate flow.

- Active valves – Controlled via external signals (pressure, electricity, etc.) for dynamic control.

- Solenoid valves – Electrically actuated for rapid, accurate flow control in automated setups.

- Miniature valves – Ultra-compact designs, ideal for integration into tight microfluidic assemblies.

- Rotary valves – High-precision valves that use mechanical rotation to switch between multiple fluidic pathways, offering low dead volume, reliable automation, and seamless multi-channel integration.

At Advanced Microfluidics (AMF), we have engineered rotary valves specifically for microfluidic systems, offering reliable, programmable, and scalable control across research, diagnostics, and industry.

Key benefits of AMF’s rotary valves

High-precision flow control

In microfluidic systems, accuracy isn’t a luxury, it’s a necessity. AMF’s rotary valves are engineered with ultra-low internal volume and no dead volume, ensuring minimal sample loss, precise dosing, and clean fluid transitions. This level of precision is critical for experiments involving sensitive reagents, limited-volume samples, or highly controlled reaction conditions.

Our technology supports stable and repeatable flow control even in the most demanding scenarios, including nanoparticle formulation, biosensor testing, or dose-response assays. By eliminating fluid retention and reducing carryover, you gain confidence in your results, and increase the efficiency of your workflow.

Automation ready

Manual sample switching slows down throughput, introduces human error, and makes scalability nearly impossible. AMF rotary valves are designed to fit directly into automated workflows, allowing you to program complex sequences, reagent delivery steps, and cleaning routines with full control and reliability.

Our automation-ready systems are compatible with electric actuation setups, giving you the flexibility to tailor your fluid control to your lab’s infrastructure. Whether you’re running diagnostics in batch, performing screening assays, or managing industrial liquid handling, our valves turn your process into a fully automated, hands-free system.

Multiplexing made easy

Modern microfluidics often requires working with multiple reagents, samples, or conditions simultaneously. AMF rotary valves make this easy with multi-port configurations — from simple 6- or 24-port setups to complex custom builds with 64 channels. This enables seamless switching between fluids without the need to manually disconnect and reconnect tubing or devices.

This multiplexing capability is ideal for high-throughput screening (HTS), synthetic biology workflows, environmental testing, and any application where time, precision, and clean transitions matter. Our valves can handle rapid switching cycles while maintaining stability, allowing you to streamline even the most complex routing systems.

OEM integration

Every system is different, which is why we don’t believe in a one-size-fits-all solution. AMF rotary valves are designed for OEM integration, with custom geometries, materials, actuation methods, and interface options tailored to your product’s exact needs. Whether you’re building a benchtop analyzer, or a scalable industrial platform, we work alongside your engineers to ensure a perfect fit.

With robust construction, compact design, and seamless electronics compatibility, our valves are made to handle repeated use in commercial systems. We support you from design to scale-up, helping you create fluidic subsystems that are reliable, reproducible, and ready for production.

flow control

High-precision flow control

In microfluidic systems, accuracy isn’t a luxury, it’s a necessity. AMF’s rotary valves are engineered with ultra-low internal volume and no dead volume, ensuring minimal sample loss, precise dosing, and clean fluid transitions. This level of precision is critical for experiments involving sensitive reagents, limited-volume samples, or highly controlled reaction conditions.

Our technology supports stable and repeatable flow control even in the most demanding scenarios, including nanoparticle formulation, biosensor testing, or dose-response assays. By eliminating fluid retention and reducing carryover, you gain confidence in your results, and increase the efficiency of your workflow.

ready

Automation ready

Manual sample switching slows down throughput, introduces human error, and makes scalability nearly impossible. AMF rotary valves are designed to fit directly into automated workflows, allowing you to program complex sequences, reagent delivery steps, and cleaning routines with full control and reliability.

Our automation-ready systems are compatible with electric actuation setups, giving you the flexibility to tailor your fluid control to your lab’s infrastructure. Whether you’re running diagnostics in batch, performing screening assays, or managing industrial liquid handling, our valves turn your process into a fully automated, hands-free system.

made easy

Multiplexing made easy

Modern microfluidics often requires working with multiple reagents, samples, or conditions simultaneously. AMF rotary valves make this easy with multi-port configurations — from simple 6- or 24-port setups to complex custom builds with 64 channels. This enables seamless switching between fluids without the need to manually disconnect and reconnect tubing or devices.

This multiplexing capability is ideal for high-throughput screening (HTS), synthetic biology workflows, environmental testing, and any application where time, precision, and clean transitions matter. Our valves can handle rapid switching cycles while maintaining stability, allowing you to streamline even the most complex routing systems.

integration

OEM integration

Every system is different, which is why we don’t believe in a one-size-fits-all solution. AMF rotary valves are designed for OEM integration, with custom geometries, materials, actuation methods, and interface options tailored to your product’s exact needs. Whether you’re building a benchtop analyzer, or a scalable industrial platform, we work alongside your engineers to ensure a perfect fit.

With robust construction, compact design, and seamless electronics compatibility, our valves are made to handle repeated use in commercial systems. We support you from design to scale-up, helping you create fluidic subsystems that are reliable, reproducible, and ready for production.

Common microfluidic challenges

& how AMF solves them

Implementing reliable fluid control in microfluidic systems isn’t always straightforward. From sample loss and flow instability to limited automation and integration headaches, the challenges are real — and they can slow down your research or production.

At Advanced Microfluidics (AMF), we’ve engineered our rotary valves to solve these issues at the source. Here’s how we help you overcome the most common roadblocks in microfluidic fluid handling:

Pain point 1: Inconsistent fluid flow and poor precision

❌ In many microfluidic setups, maintaining a stable flow rate is difficult due to mechanical limitations or unstable control systems. This leads to inaccurate dosing, cross-contamination, and unreliable experimental results.

✅ AMF solution: Our rotary valves are engineered for repeatable, high-precision flow control, ensuring accuracy and consistency in even the most sensitive fluid handling tasks.

Pain point 2: High internal volume and dead zones

❌ Valves with large internal cavities or poorly designed geometries trap liquid, causing sample loss and increasing the risk of contamination. This is especially problematic when working with rare or expensive reagents.

✅ AMF solution: AMF rotary valves are optimized with ultra-low internal volume and no dead volume, maximizing sample recovery and minimizing waste.

Pain point 3: Manual processes slowing down workflows

❌ Manual switching between samples or reagents is time-consuming, error-prone, and incompatible with high-throughput or automated lab environments.

✅ AMF solution: Our valves are automation-ready, fully programmable, and designed for seamless integration into automated liquid handling systems. Gain speed, repeatability, and reliability.

Pain point 4: Integration problems with complex systems

❌ Standard valves often don’t fit the specific needs of modern microfluidic platforms — whether due to incompatible connections, control protocols, or physical footprint.

✅ AMF solution: AMF offers customizable OEM rotary valve designs that adapt to your system architecture, ensuring smooth integration and long-term scalability.

Pain point 5: Limited channel control or switching options

❌ Many valves support only basic on/off control or single-channel switching, which limits your ability to handle complex assays or multi-reagent workflows.

✅ AMF solution: Our rotary valves support efficient multiplexing, allowing you to switch between multiple channels, reagents, or samples within a single compact module.

Pain point 6: Fragile or unreliable components in demanding environments

❌ Some microfluidic components fail under pressure, wear out quickly, or require constant maintenance, disrupting critical experiments or production runs.

✅ AMF solution: Built for durability and repeatable performance, our rotary valves are designed to handle high pressure, harsh chemicals, and continuous operation without failure.

Pain point 7: Lack of customization and support

❌ Off-the-shelf components may not meet your specific performance or design requirements, and support is often limited or non-technical.

✅ AMF solution: AMF works closely with you to co-develop tailored solutions — from fluidic design to integration support — ensuring that your system performs exactly as needed.

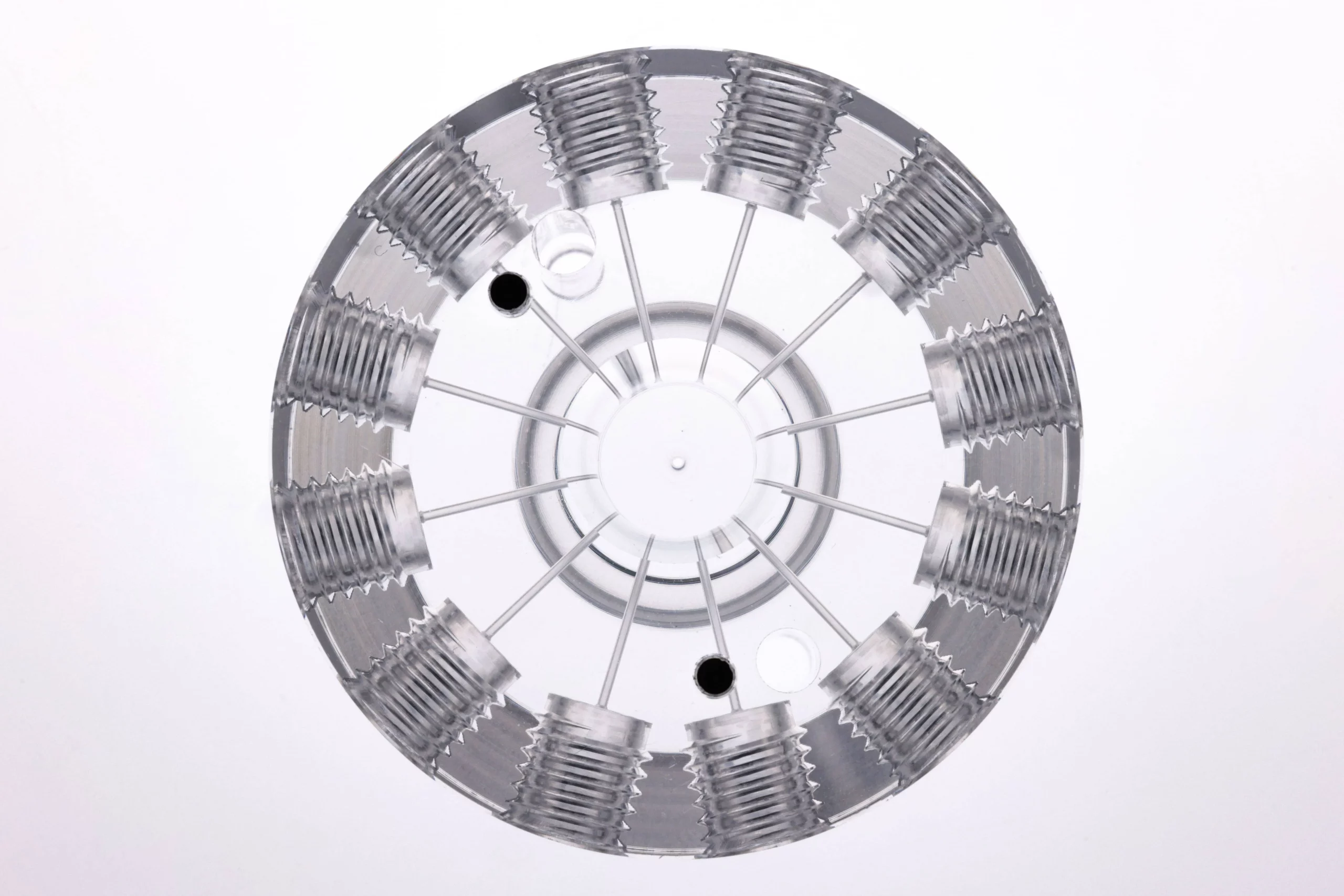

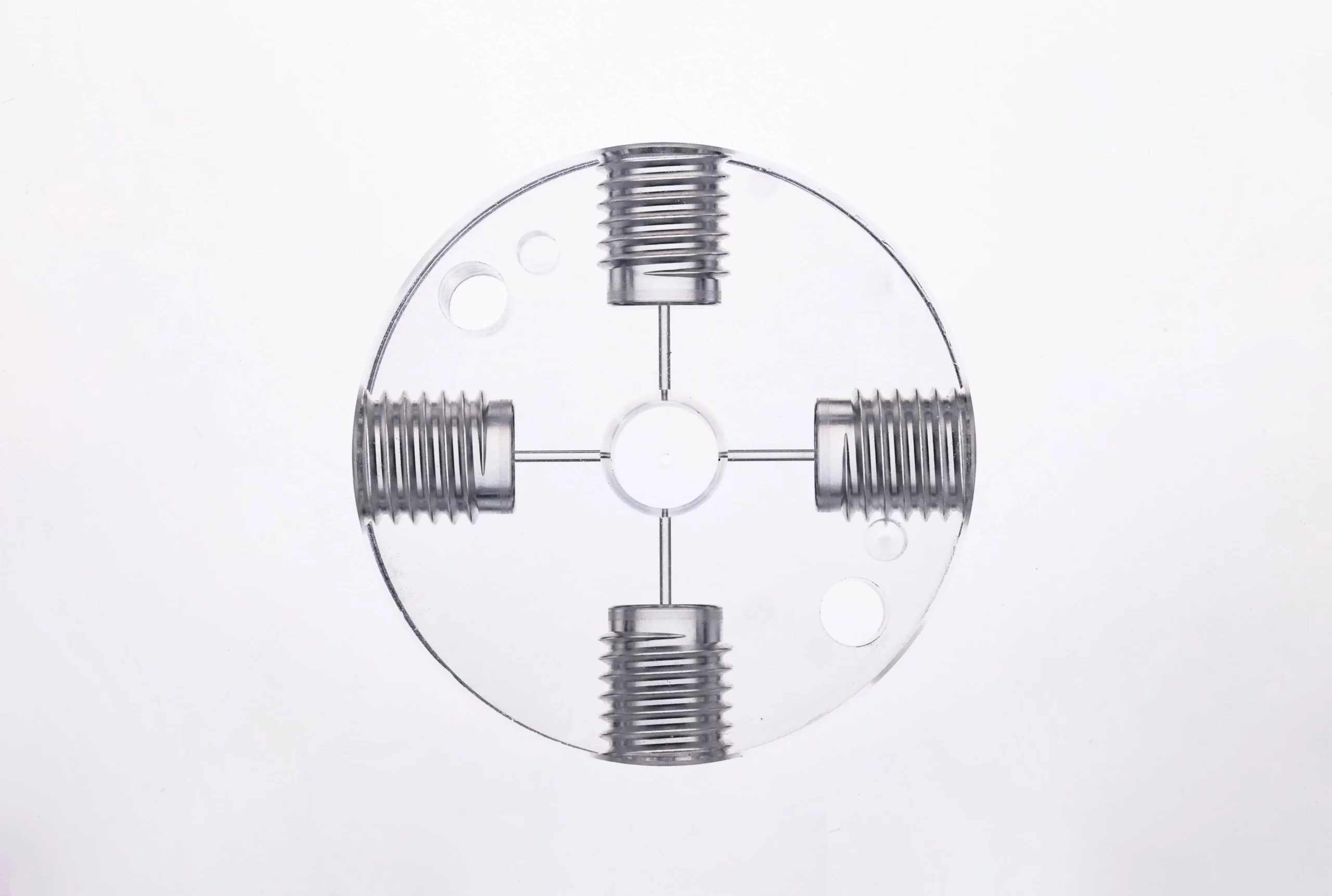

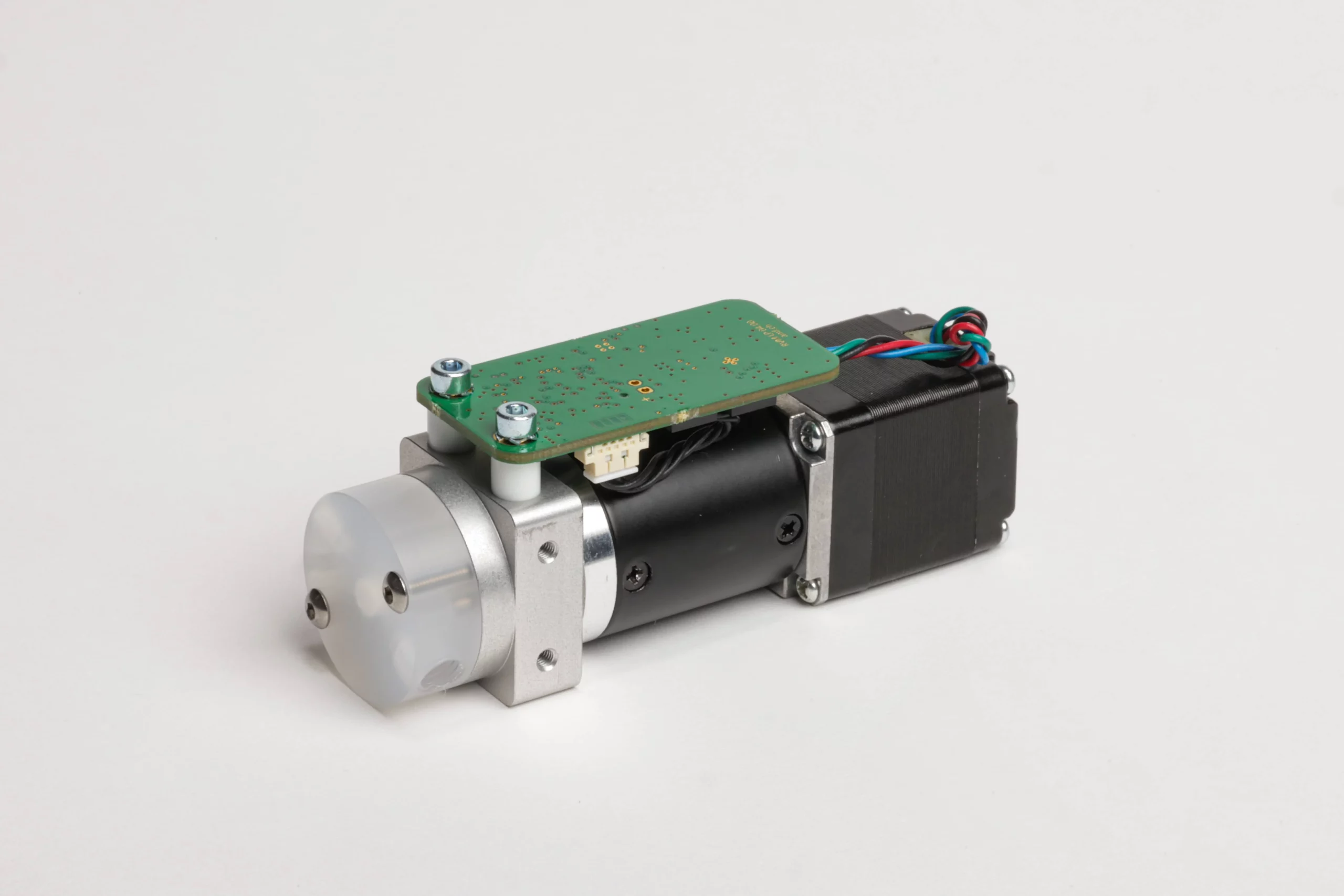

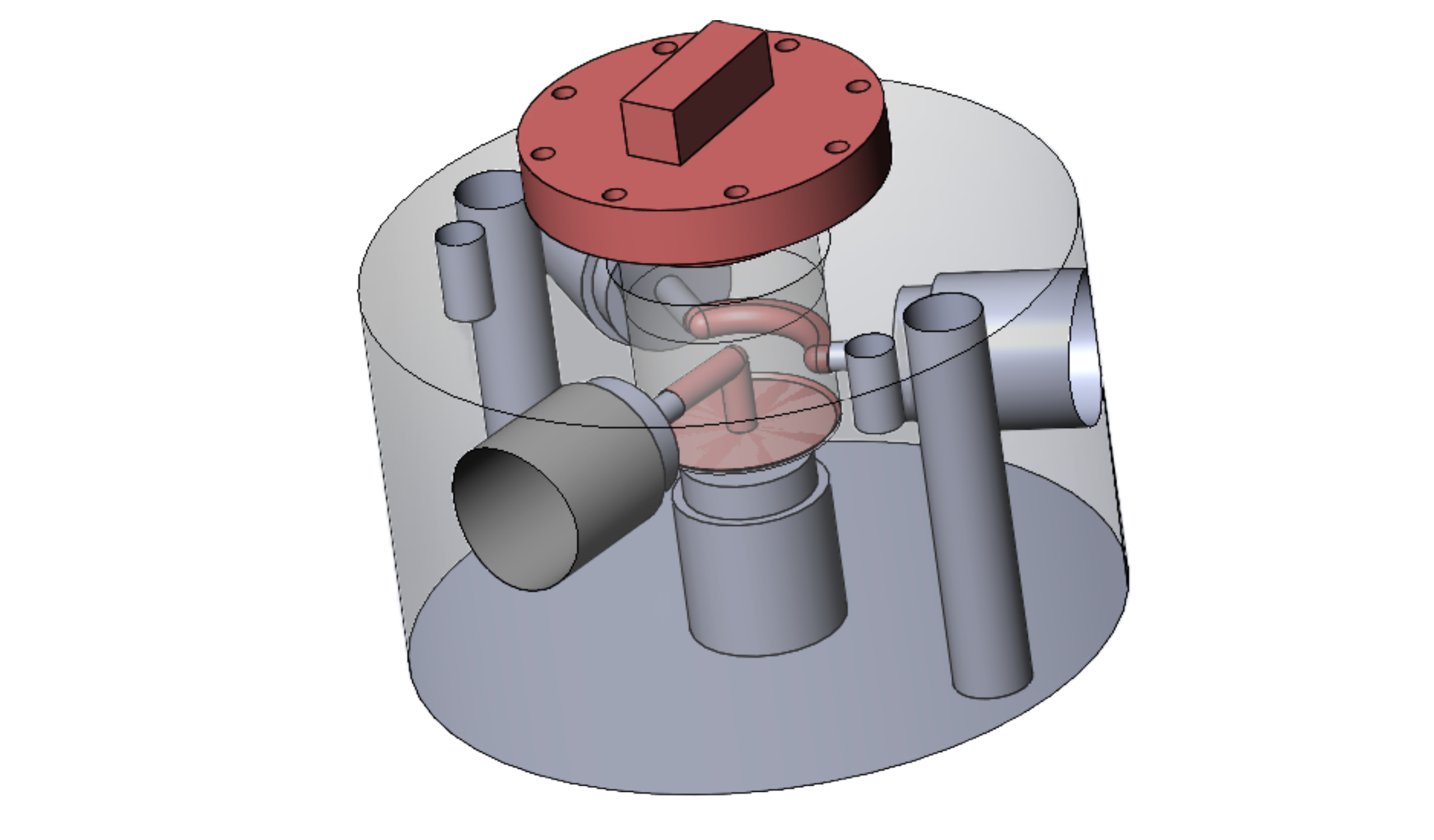

RVM – Industrial Microfluidic Rotary Valve

Precision-engineered for automated microfluidic systems

The RVM is AMF’s flagship rotary valve, designed for high-precision fluid handling in automated microfluidic applications. With ultra-low internal volume and no dead volume, it ensures minimal sample loss and contamination, making it ideal for diagnostics, life sciences, and industrial processes.

Key features:

- Versatile configurations: Available in distribution, switch, and on/off functions with up to 24 ports, accommodating complex fluid routing needs.

- Ultra-low internal volume: Channel diameters from 0.5 mm to 1 mm, achieving internal volumes as low as 600 nL, optimizing reagent usage and no dead volume.

- Motor options: Choose between fast (400 ms switching) or low-power motors to suit your application’s speed and energy requirements.

- Integrated position sensor: Ensures precise valve positioning and reliable operation within automated systems.

- Robust construction: Wetted materials like PCTFE and PTFE offer broad chemical compatibility and durability.

- Easy integration: Standard 1/4-28 UNF fittings and communication interfaces (USB mini, 9-pin D-Sub) facilitate seamless system integration.

Applications: Ideal for automated liquid handling, sample preparation, reagent switching, and integration into OEM devices across various industries.

Lead Time: Approximately 4 weeks.

Model & motor specifications

| Reference | Configuration | Power | Weight | Dimensions | Min. Switching time 180° | PCB functionalities |

|---|---|---|---|---|---|---|

| P200-O | Low power mode | 5-10 VDC, 0.5 A peak | 250 g | 29 x 38.3 x 111.8 mm | 1.5 s | Driver, Encoder |

| P201-O | Fast motor | 18-24 VDC, 2 A peak | 450 g | 42.3 x 60 x 95.9 mm | 400 ms | Driver, Encoder |

| P211-O | Fast motor | 18-24 VDC, 2 A peak | 450 g | 42.3 x 60 x 95.9 mm | 400 ms | Encoder |

Other specifications

| Operating temperature | 15 – 40°C (59-104°F) |

| Operating humidity | 20-80%, non condensing |

| Max. pressure | 7 bars (102 psi) |

| Wetted materials | PTFE or UHMW – PE, PCTFE |

| Channel diameter | 0.5 mm (0.020 in) or 1 mm (0.039 in) (other upon request) |

| Internal volume | 2.5 – 13.7 μL port-to-port (configuration dependent) |

| Carryover volume | 0.55 – 6.7 μL port-to-port (configuration dependent ) |

| Dead volume | None |

| Tube port fittings | Standard 1/4 – 28 UNF, flat-bottom |

| Electrical interface | USB mini, 9–pin D–Sub (fast motor model only) |

| Communication type | Serial, I2C (other upon request) |

Valve specifications

DISTRIBUTION SERIES

| Ref. | Configuration | Wetted materials | Internal volume | Carryover volume | Fluid path diameter | Max. pressure |

|---|---|---|---|---|---|---|

| V–D–1–6–050–C–P | 6 ports low carryover volume | PCTFE, PTFE | 2.5 μL | 1.5 μL | 0.5 mm | 7 bars |

| V–D–1–8–050–C–P | 8 ports low carryover volume | PCTFE, PTFE | 2.5 μL | 1.5 μL | 0.5 mm | 7 bars |

| V–D–1–8–100–C–P or U | 8 ports low carryover volume | PCTFE, PTFE or UHMW–PE | 13.8 μL | 6.7 μL | 1 mm | 7 bars |

| V–D–1–10–050–C–P or U | 10 ports low carryover volume | PCTFE, PTFE or UHMW–PE | 3.5 μL | 1.7 μL | 0.5 mm | 7 bars |

| V–D–1–10–100–C–P or U | 10 ports low carryover volume | PCTFE, PTFE or UHMW–PE | 13.8 μL | 6.7 μL | 1 mm | 7 bars |

| V–D–1–12–050–C–P or U | 12 ports low carryover volume | PCTFE, PTFE or UHMW–PE | 3.5 μL | 1.7 μL | 0.5 mm | 7 bars |

| V–D–2–24–050–K-P | 24 ports low carryover volume | PEEK, PTFE | 3.6 μL | 2.2 μL | 0.5 mm | 7 bars |

ON/OFF SERIES

| Ref. | Configuration | Wetted materials | Internal volume | Carryover volume | Fluid path diameter | Max. pressure |

|---|---|---|---|---|---|---|

| V–O–1–2–050–C–P | 2 ports | PCTFE, PTFE | 2.8 μL | - | 0.5 mm | 7 bars |

SWITCH SERIES

| Ref. | Configuration | Wetted materials | Internal volume | Carryover volume | Fluid path diameter | Max. pressure |

|---|---|---|---|---|---|---|

| V–S–1–4–050–C–P | 4 ports ultra-low carryover volume | PCTFE, PTFE | 2.6 μL | 0.8 μL | 0.5 mm | 7 bars |

| V–S–1–6–050–C–P | 6 ports ultra-low carryover volume | PCTFE, PTFE | 2.4 μL | 0.6 μL | 0.5 mm | 7 bars |

Valve heads are interchangeable. Other models available upon request.

The above specifications are typical for our components and may vary due to multiple parameters / factors (e.g. fluid type, usage conditions…). Specifications are subject to change.

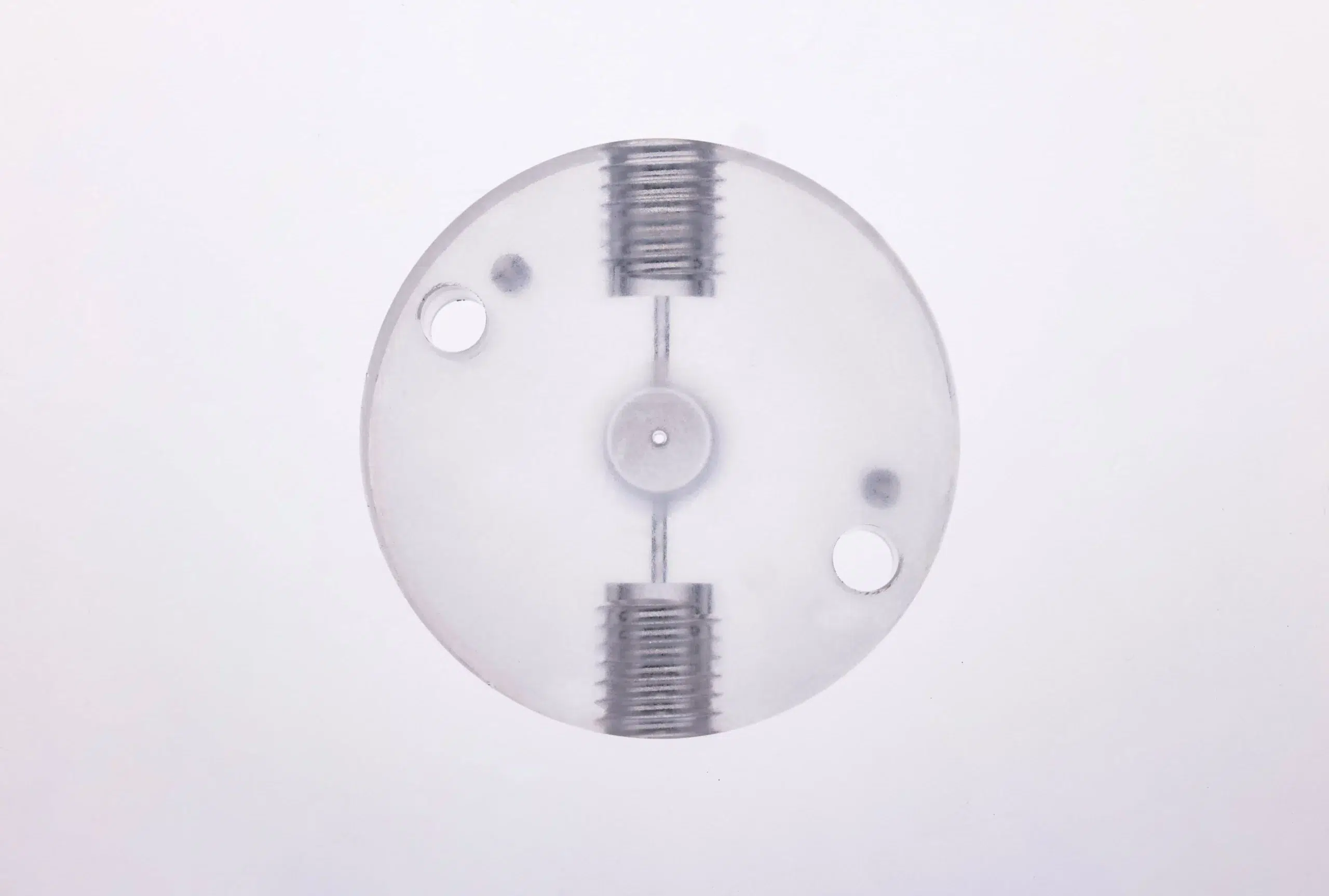

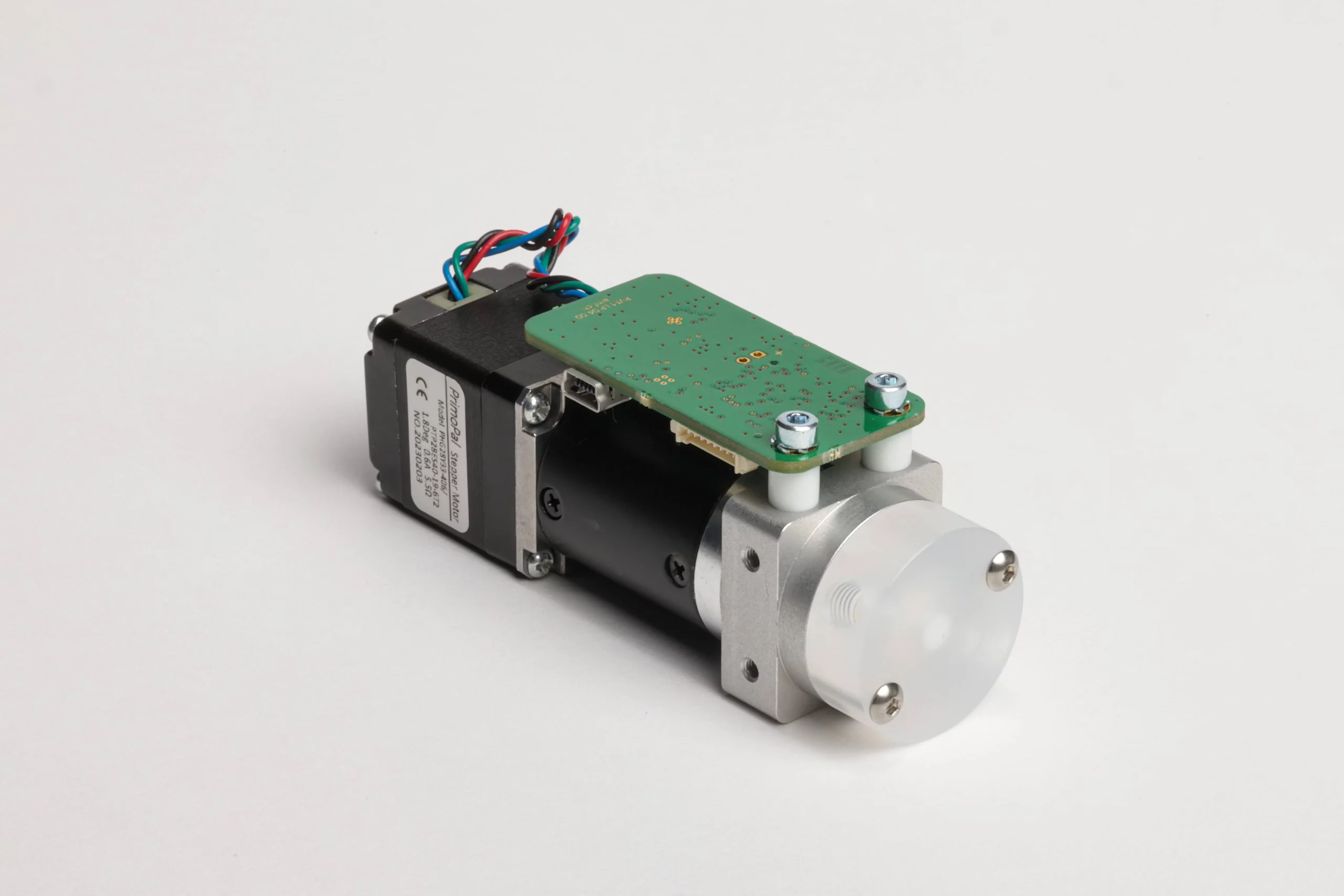

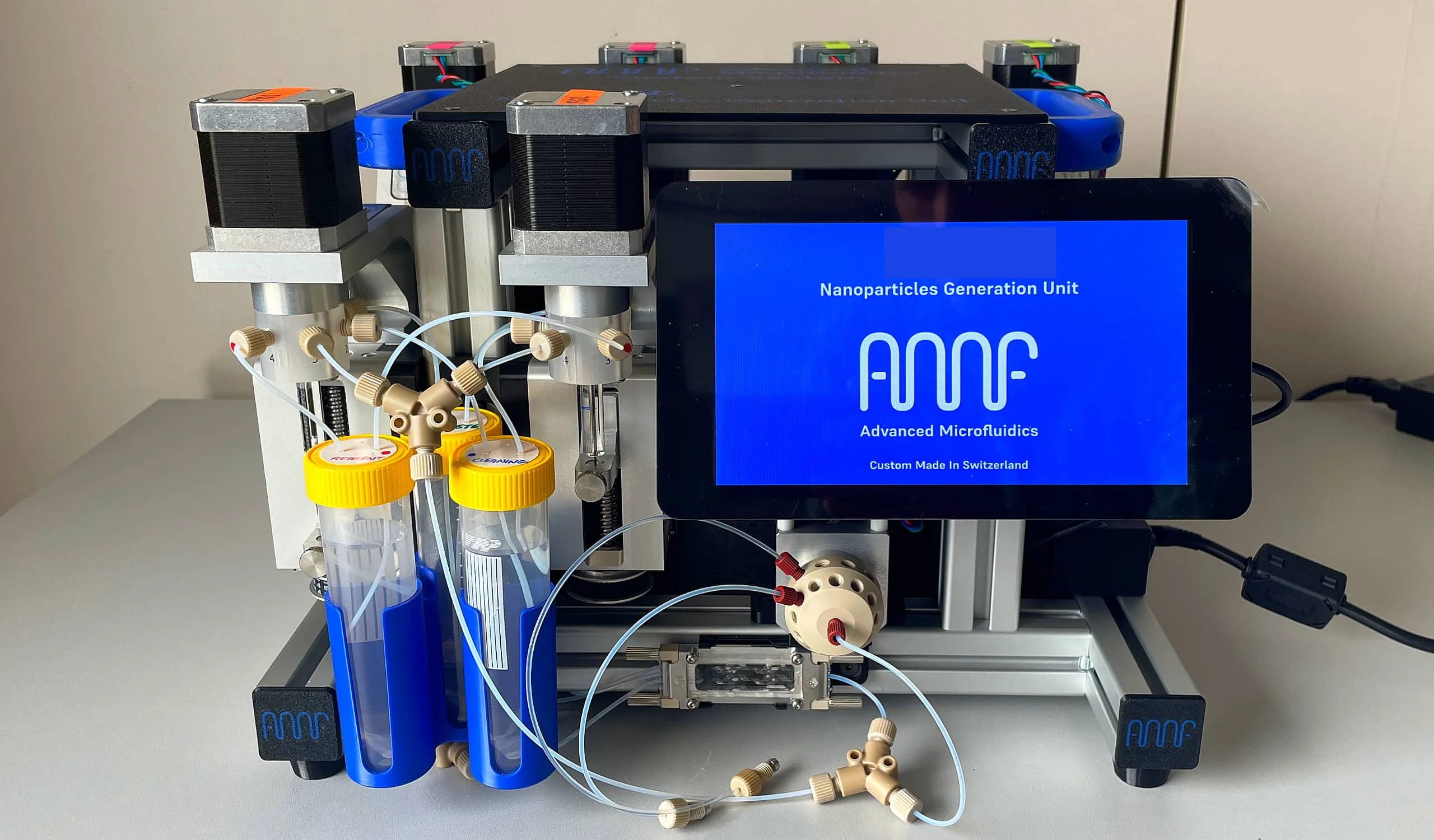

SPM – Industrial Programmable Syringe Pump

Integrated precision for automated microfluidic workflows

The SPM is AMF’s all-in-one solution that combines a high-precision syringe pump with a low-volume rotary valve. Engineered for seamless integration into automated microfluidic systems, it ensures accurate fluid handling with minimal dead volume, making it ideal for applications in diagnostics, life sciences, and industrial processes.

Key features:

- All-in-one rotary valve + syringe pump: Combines fluid switching and precise dosing in a single compact unit — simplifying integration, reducing tubing, and saving space in your microfluidic system.

- Ultra-low internal volume & no dead volume: Channel diameters as small as 0.5 mm and volumes down to 600 nL minimize fluid waste and maximize reagent recovery.

- Minimal carryover and contamination risk: The fluid path is engineered with optimized geometries and inert materials to eliminate dead volume and drastically reduce sample-to-sample carryover — ideal for sensitive assays and high-purity workflows.

- Ultra-low & stable flow rates: Delivers flow rates as low as 7.45 nL/min, ideal for highly sensitive experiments. The HD (high-definition) version provides ultra-stable flow, perfect for precision dosing and long-duration experiments.

- Sequential programmable control: Run complex aspiration and dispense protocols across multiple ports with full software control over timing, flow direction, and volume.

- Customizable for OEM integration: Compact and robust, the SPM is designed to be embedded directly into commercial systems — with flexible layout options and material customization available.

- Flexible syringe compatibility: Supports syringe volumes from 50 µL to 5 mL, giving you precise control whether you’re handling microliters or milliliters.

- Plug-and-play communication: Equipped with USB mini, RS232, and RS485 interfaces for easy integration with your control software or automation platform.

Applications: Ideal for automated liquid handling, sample preparation, reagent switching, and integration into OEM devices across various industries.

Lead Time: Approximately 4 weeks.

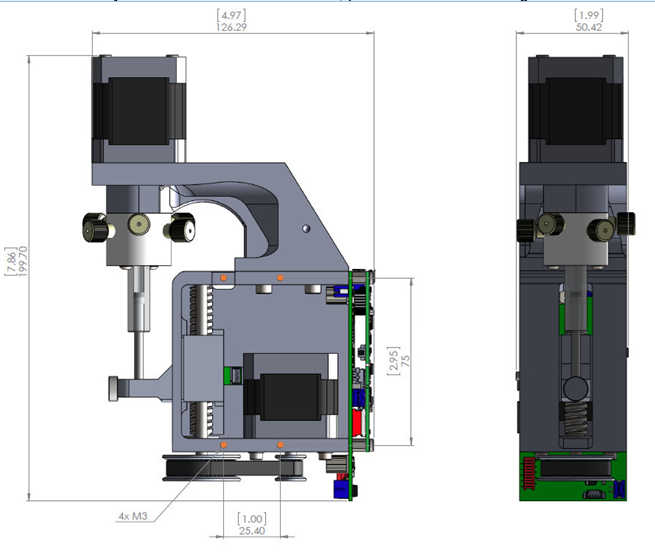

SPM P100-O (50 µL to 1 mL syringe size)

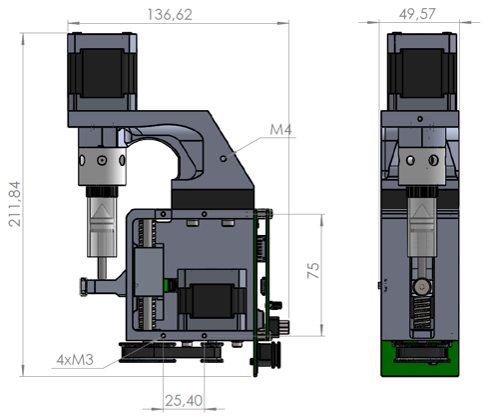

SPM P101-O (2.5 mL & 5 mL syringe size)

Other specifications

| SPM P100-O | SPM P101-O (2.5 & 5 mL syringe size) | |

|---|---|---|

| Operating temperature | 15 – 40°C (59-104°F) | 15-45°C (59-113°F) |

| Operating humidity | 20-80%, non condensing | 20-80%, non-condensing |

| Max. pressure | 5 bars (72 psi) | 5 bars (72 psi) |

| Wetted materials | PTFE or UHMW-PE, PCTFE and borosilicate glass | PTFE or UHMW-PE, PCTFE and borosilicate glass |

| Dead volume | None | None |

| Carryover volume | 1.5 – 10.2 μL (configuration dependent) | 18.1 – 34 μL (configuration dependent) |

| Plunger travel | 30 mm with 96,000 micro-steps for nearly pulseless flow | 30 mm with 96,000 micro-steps for nearly pulseless flow |

| Plunger resolution | Selectable 3,000 steps (standard) / 24,000 steps (high) | Selectable 3,000 steps (standard) / 24,000 steps (high) |

| Plunger drive | Screw drive with linear encoder for step loss detection | Screw drive with linear encoder for step loss detection |

| Syringes configurations | 50µL to 1mL syringe size | 2.5 & 5 mL syringe size |

| Valves configurations | Zero-dead-volume multi-port distribution with angular encoder | Zero-dead-volume multi-port distribution with angular encoder |

| Tube port fittings | Standard 1/4 – 28 UNF, flat-bottom | Standard 1/4 – 28 UNF, flat-bottom |

| Cross-contamination | Typically from 1/100 to 1/1000 per cleaning cycle | Typically from 1/100 to 1/1000 per cleaning cycle |

| Accuracy | < 1% deviation from expected value at full stroke | < 1% deviation from expected value at full stroke |

| Electrical interface | USB mini, 9–pin D–Sub (other upon request) | USB mini, 9–pin D–Sub (other upon request) |

| Interface | USB mini, RS-232, RS-485 | USB mini, RS-232, RS-485 |

| Communication type | Serial (serial over USB, RS-232, RS-485) | Serial (serial over USB, RS-232, RS-485) |

| Power | 18 VDC, 2.2 A peak, 40 W (18 VDC optimized for battery use) | 18 VDC, 2.2 A peak, 40 W (18 VDC optimized for battery use) |

| Time for full stroke | 2 – 6000 seconds | 2 – 6000 seconds |

| Dimensions | 199.7 x 126.3 x 50.5 mm | 211.84 x 136.62 x 49.57 mm |

| Weight | 1.5 kg | 1.6 kg |

Valve specifications for P100-O

| Ref. | Configuration | Wetted materials | Internal volume | Carryover volume | Fluid path diameter | Max. pressure |

|---|---|---|---|---|---|---|

| V–D–2–6–050–C–P | 6 ports ultra-low carryover volume | PCTFE, PTFE | 5.2 μL | 1.5 μL | 0.5 mm | 7 bars |

| V–D–1–6–050–C–P | 6 ports low carryover volume | PCTFE, PTFE | 3.6 μL | 2.6 μL | 0.5 mm | 7 bars |

| V–D–1–8–050–C–P | 8 ports low carryover volume | PCTFE, PTFE | 3.6 μL | 2.6 μL | 0.5 mm | 7 bars |

| V–D–1–8–100–C–P or U | 8 ports low carryover volume | PCTFE, PTFE or UHMW–PE | 14.9 μL | 7.8 μL | 1 mm | 7 bars |

| V–D–1–10–050–C–P or U | 10 ports low carryover volume | PCTFE, PTFE or UHMW–PE | 4.6 μL | 2.8 μL | 0.5 mm | 7 bars |

| V–D–1–10–100–C–P or U | 10 ports low carryover volume | PCTFE, PTFE or UHMW–PE | 14.9 μL | 7.8 μL | 1 mm | 7 bars |

| V–D–1–12–050–C–P or U | 12 ports low carryover volume | PCTFE, PTFE or UHMW–PE | 4.6 μL | 2.8 μL | 0.5 mm | 7 bars |

Valve specifications for P101-O (2.5 & 5 mL)

| Ref. | Configuration | Wetted materials | Internal volume | Carryover volume | Fluid path diameter | Max. pressure |

|---|---|---|---|---|---|---|

| V-D-1-12-050-C-P | 12 ports low carryover volume | PCTFE, PTFE | 15.4 μL | 13.6 μL | 0.5 mm | 7 bars |

Valve heads are interchangeable. Other models and customs available upon request for P100-O & P101-O.

Syringe specifications

| Reference | Volume | Plunger material | Min. flow rate | Max. flow rate | Min. dosing volume |

|---|---|---|---|---|---|

| S–50–P | 50 μL | PTFE | 0.00745 μL/min | 1 500 μL/min | 0.1 μL |

| S–100–P | 100 μL | PTFE | 0.0149 μL/min | 3 000 μL/min | 0.2 μL |

| S–250–P | 250 μL | PTFE | 0.03725 μL/min | 8 000 μL/min | 0.5 μL |

| S–500–P or S–500–U | 500 μL | PTFE or UHMW-PE | 0.0745 μL/min | 15 000 μL/min | 1 μL |

| S–1000–P | 1000 μL | PTFE | 0.149 μL/min | 30 000 μL/min | 2 μL |

| S–2500–P | 2.5 mL | PTFE | 0.3725 μL/min | 75 000 μL/min | 5 μL |

| S–5000–P | 5 mL | PTFE | 0.745 μL/min | 150 000 μL/min | 10 μL |

Chemical compatibility The wetted materials being PTFE, PCTFE and borosilicate glass, this pump offers an exceptional compatibility to most chemicals and biological samples.

The above specifications are typical for our components and may vary due to multiple parameters / factors (e.g. fluid type, usage conditions…). Specifications are subject to change.

Optional:

It is possible to add a heating/cooling module around the syringe to suit your specific application.

Custom Microfluidic Solutions – Components & Systems

Tailored microfluidic innovation from concept to production

At Advanced Microfluidics (AMF), we specialize in designing and manufacturing bespoke microfluidic components and systems that align precisely with your project’s requirements. Whether you’re developing a novel lab-on-a-chip device, scaling up for industrial production, or integrating microfluidics into existing platforms, our team collaborates with you to deliver solutions that ensure precision, reliability, and seamless integration.

Key features:

- Fully customizable designs: From microfluidic valves and connectors to complete fluidic systems, we offer designs tailored to your specific application needs, ensuring optimal performance and integration.

- Scalable manufacturing: Our capabilities range from prototyping to mass production, allowing for a smooth transition from development to commercialization without compromising quality.

- Material versatility: We work with a variety of materials, including PCTFE, PTFE, and borosilicate glass, to meet chemical compatibility and durability requirements.

- Precision engineering: Utilizing advanced manufacturing techniques, such as 5-axis CNC machining, we achieve high-precision components with minimal dead volume and exceptional surface finish.

- Quality assurance: Each component undergoes rigorous quality control processes, including visual inspections, surface roughness measurements, and fluidic testing, to ensure reliability and performance.

- Seamless integration: Our custom solutions are designed for easy integration into your existing systems, with options for standard fittings and communication interfaces to match your setup.

Applications:

Ideal for a wide range of applications, including:

- Lab-on-a-chip devices

- Automated liquid handling systems

- Diagnostic platforms

- Pharmaceutical development

- Environmental monitoring

- And much more

Lead Time: Approximately 6 weeks, depending on project complexity.

Looking for detailed specs?

Our brochure includes full technical specifications, integration examples, and product configurations — tailored to help you plan your microfluidic system.

Our skills in a few numbers

We've sold over 19,000 products in the last few years, earning the trust of countless satisfied customers.

We've successfully produced over 5,700 valves in the last few years, maintaning high quality standards.

Our growing client base now includes more than 250 partners, representing a diverse range of industries.

Benefit from our efficient production and delivery, with an average lead time of just 4 weeks for your projects.

Microfluidic Valves, Automation & Integration - FAQ

A microfluidic rotary valve is a compact flow control component that uses a rotating mechanism to direct liquids between multiple microchannels. It enables precise, programmable switching for complex fluid handling tasks.

AMF valves are specifically designed for microfluidic use — with ultra-low internal volume, no dead volume, and OEM-ready integration. They’re built for automation, precision, and reliability in demanding environments.

Low dead volume means minimal liquid remains trapped inside the valve. This reduces sample loss and cross-contamination — essential for sensitive assays and high-value reagents.

Yes. Our valves are designed for seamless integration with automation systems, allowing real-time control of fluid flow in research instruments, diagnostic devices, or industrial platforms.

Multiplexing is the ability to handle multiple fluid channels or samples in parallel. AMF’s rotary valves support multiplexing by enabling fast, clean switching between several fluidic pathways within a single device.

Absolutely. Our valves are designed to connect with standard tubing, chips, and pumps. We also offer custom fittings and configurations to ensure compatibility with your specific system.

They’re used in diagnostics, cell culture, nanoparticle synthesis, continuous flow chemistry, environmental testing, and more — anywhere precise, programmable fluid control is required.

Yes. We specialize in OEM solutions and can adapt valve geometry, materials, and integration to fit your system architecture and application needs.

A programmable syringe pump is a precision instrument that controls fluid flow by moving a syringe plunger at a defined speed and volume. It allows for accurate dosing, gradient formation, or continuous flow in microfluidic setups.

Our syringe pumps offer high-resolution plunger control (down to micrometers per second), ensuring ultra-precise flow rates for sensitive microfluidic applications, including diagnostics, cell culture, and particle synthesis.

Yes. AMF’s syringe pumps are fully programmable and compatible with automation platforms, making them ideal for repetitive processes like reagent delivery, sample preparation, or time-based dosing sequences.

The combination allows for fully automated liquid routing and dosing. You can draw and dispense fluids through multiple channels without manual intervention, perfect for workflows involving multiple reagents or samples.

Absolutely. We offer both compact, benchtop versions for research labs (like the LSPone) and modular designs for OEM integration (like the SPM), all optimized for microfluidic performance and reliability.

Our standard lead time is just 4 weeks, much faster than most industry suppliers. We also offer support for urgent requests and production ramp-up.

We offer full technical support — from integration advice to troubleshooting — with access to our engineering team. We’re here to ensure your system performs exactly as expected.

Looking for detailed specs?

Our brochure includes full technical specifications, integration examples, and product configurations — tailored to help you plan your microfluidic system.